Desalination system in Libya

About the customer

A customer of ours has designed a turnkey desalination system for seawater in containers that extracts water from a well for the production of drinking water. The total production is about 300 m³/day and because of the warm environment in the Libyan desert, a pre-treatment disinfection step is very important to prevent membrane fouling.

The question

Since the use of chlorine can damage the membranes of a reverse osmosis installation, the customer wanted to limit the use of chlorine.

The solution

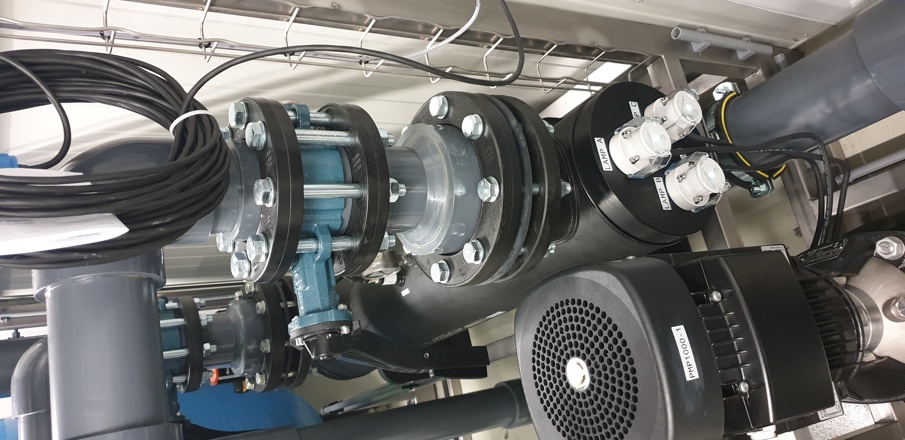

This is where VGE Pro's UV systems come into the picture. Placed directly after the multimedia filter to ensure that no suspended particles enter the water, the UV-C system can handle a peak flow of 25 m³/h. The UV-C light immediately deactivates micro-organisms that are the cause of biofilm formation, which extends the life of the membranes and can delay maintenance. Since the system must withstand hot salt water, all materials are corrosion-resistant, such as the irradiation chamber which is made of HDPE. To ensure effectiveness, a UV sensor and temperature sensor are included to ensure consistent quality and prevent overheating in situations where the flow stops

Curious to learn more about what we do? Take a look at one of our other cases.